What are the maintenance requirements for the Motor Propeller Test Kit?

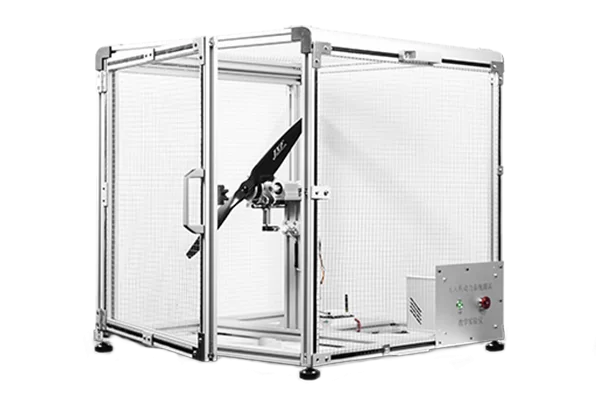

When it comes to ensuring optimal performance and longevity of your Motor Propeller Test Kit, proper maintenance is paramount. We understand the criticality of this equipment for your operations and are here to guide you through the intricate details of maintaining your Motor Propeller Test Kit for optimal results.

Regular Inspection for Wear and Tear

Regular inspections are the cornerstone of effective maintenance. Begin by visually assessing the overall condition of the Motor Propeller Test Kit. Look for any signs of wear and tear on the propeller, shaft, and other essential components. Identifying potential issues at an early stage can prevent costly repairs down the line.

Lubrication for Enhanced Performance

Proper lubrication is key to the smooth operation of your Motor Propeller Test Kit. Ensure that you follow the manufacturer's guidelines for the correct lubricants and apply them at the recommended intervals. Lubrication not only reduces friction but also prevents corrosion, extending the life of critical components.

Calibration and Accuracy Checks

For accurate test results, regular calibration is imperative. Periodically check the calibration of the Motor Propeller Test Kit to maintain precision. Any deviations from the standard readings should be promptly addressed to ensure the reliability of the test results.

Cleaning and Decontamination

Maintaining a clean and contamination-free testing environment is crucial. Regularly clean the propeller and associated components to prevent debris buildup, which can compromise the accuracy of the test results. Follow the manufacturer's guidelines for proper cleaning procedures and use approved cleaning agents to avoid any damage.

Related links:Mastering the Art of Utilizing a Thrust Stand for Precise Measurements

Understanding the Power of Cylindrical Lenses and Spherical Lenses in Optics

The Evolution of Digital DC Millivoltmeters: From Analog to Precision

Why Choose UV Grade Fused Silica Plano-Convex Lenses?

High Voltage Testing

Electrical System Inspection

A thorough inspection of the electrical system is vital for the Motor Propeller Test Kit's functionality. Check for loose connections, damaged wires, or any signs of electrical issues. Addressing these concerns promptly can prevent disruptions in testing and ensure the safety of the equipment.

Periodic Component Replacement

Certain components of the Motor Propeller Test Kit may have a finite lifespan. Keep track of the usage hours and replace components such as bearings, seals, and gaskets at the recommended intervals. This proactive approach can prevent unexpected failures and downtime.

Environmental Considerations

Consider the environmental conditions in which the Motor Propeller Test Kit operates. Extreme temperatures, humidity, or exposure to corrosive substances can impact the equipment's performance. Implementing protective measures, such as climate-controlled storage and regular corrosion checks, can mitigate these risks.

Training for Maintenance Personnel

Ensure that your maintenance personnel are well-trained on the specific requirements of the Motor Propeller Test Kit. Proper training enhances their ability to identify potential issues, perform routine maintenance tasks, and respond effectively to any unforeseen challenges.

Conclusion

In conclusion, the maintenance of a Motor Propeller Test Kit demands a systematic and proactive approach. From regular inspections to precise calibration and component replacements, each aspect plays a crucial role in ensuring the equipment's optimal performance. By adhering to these comprehensive maintenance requirements, you not only extend the lifespan of your Motor Propeller Test Kit but also enhance the accuracy and reliability of your test results.